Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

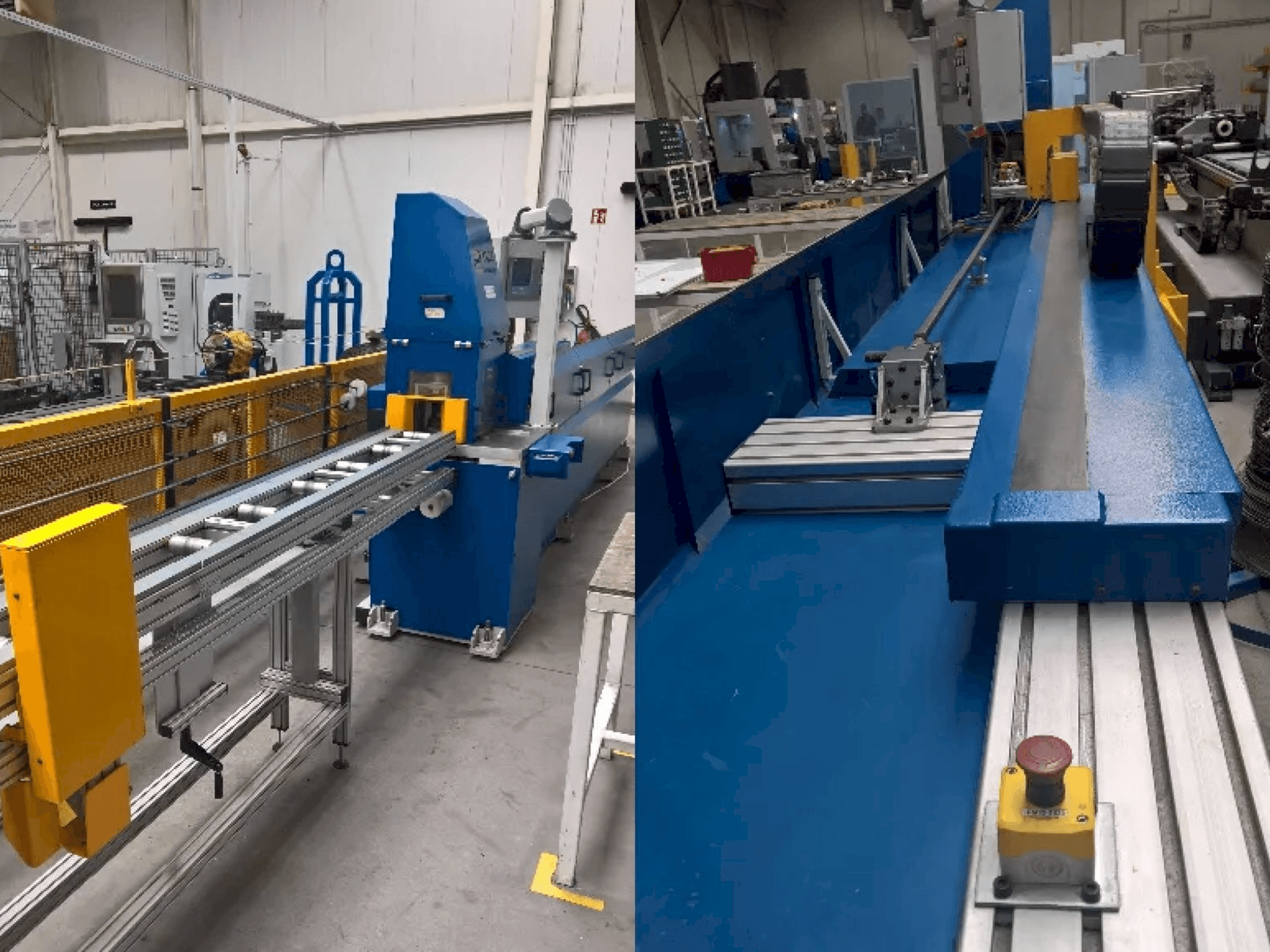

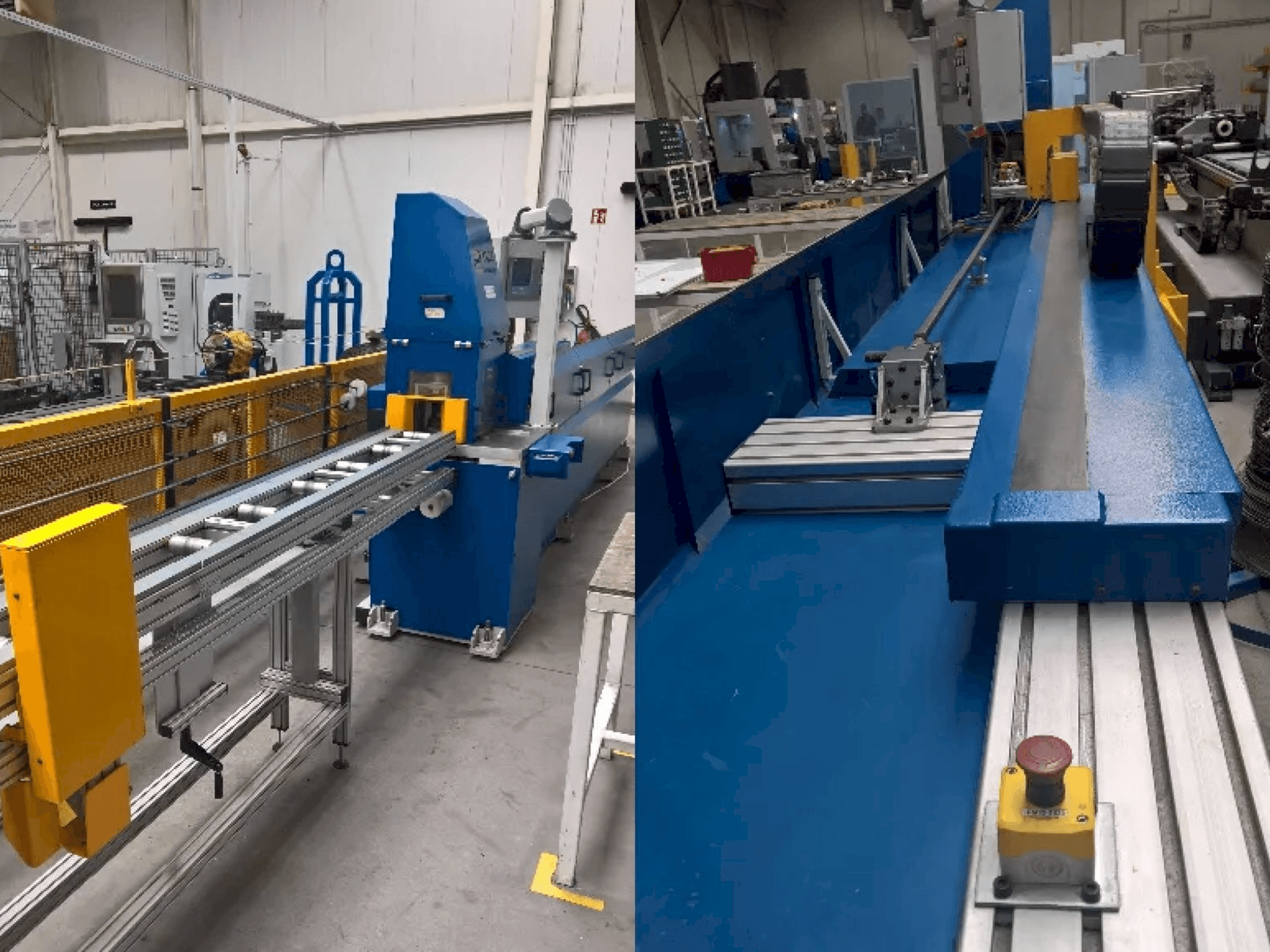

PARS - HPM SIRIUS PLUS - 3000/6 LH-1PL-PUN-PAR-2014-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para chapa

- PARS HPM SIRIUS PLUS - 3000/6 LH-1 Punching Machine

This PARS HPM SIRIUS PLUS - 3000/6 LH-1 Punching Machine was manufactured in Czech Republic in the year 2014. This machine works with a punching force of 151 kN and a maximum sheet thickness of 4 mm. Hydraulic machine with automatic profile feed by means of an electric linear drive with a magnetic coupling. The presented machine is the highest series of machines designed to work under high time load (3 shift work). The presented device is a new one, improved in 2012. machine model (the latest models of Siemens controllers). The machine is controlled fully automatically thanks to the CNC digital control. Depending on the equipment, the profiles can be round, rectangular, square, triangular, oval, type D or open. Thanks to the special hydraulic and electronic control solution (option), the press can work in both directions. This solution allows the use of special equipment to punch holes and pull out flanges in steel profiles.

Resumen

- marca: PARS

- año: 2014

- MODELO: HPM SIRIUS PLUS - 3000/6 LH-1

- tipo de aplicación: Punzonado

- Ubicación: Polonia

- tipo de máquina: Máquina de punzonado CNC

- Marca de unidad de control: SIEMENS

Información técnica - PARS HPM SIRIUS PLUS - 3000/6 LH-1

Unidad de Control

- Marca del control: SIEMENS

Dimensiones

- Profundidad de la máquina: 2100 mm

- Altura de la máquina: 1200 mm

- Peso de la máquina: 2100 kg

Recorrido

- Recorrido eje X: 6000 mm

Especificación Técnica

- Fuerza de perforación: 151 Kn

Información adicional

Machine Benefits

Qualitative Machine Benefits

- Material feed. Automatic, linear electric motor with separation from the external environment protection against punching profiles with a length outside the specified tolerance

- Measurement of the laser profile length

- Quick punching tool change system

- Turntable for pipes 0-180º

- Automatic lubrication, micron oil mist spray

- Program control of the range of movement of the hydraulic cylinder of the press

- Memory of punching programs

- Tool change time / 1 head approx. 15-20 min.

Technical Machine Benefits

- Possibility of punching in 4 sides of the profile and programming in one recipe yes

- Punching speed 0. 9-1. 2 s / hole

- Positioning accuracy up to ± 0. 1 mm between holes

- Profile / tube size 80xl00mm, d = 80mm

- Feeding / receiving table with hydraulic height adjustment

- Profile holder automatic, hydraulic

- Pneumatic blow-out of waste

- Remote machine diagnostics via the internet (vpn)

- Uploading punching programs via the company's internal network or usb memory stick

- The ability to edit programs on a pc

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos

Productos relacionados con PARS HPM SIRIUS PLUS - 3000/6 LH-1

EM2510NT

AMADA - Prensa punzonadora CNC

Trupunch 5000

TRUMPF - Prensa punzonadora CNC

Trumatic 5000 R

TRUMPF - Prensa punzonadora CNC

Compact 750 (2018)

BOSCHERT - Prensa punzonadora de torreta

LP6

Finn-Power - Combinación de punzonado y láser

HACO Q5 (2014)

Tecnology - Prensa punzonadora CNC

F6-25 5B

Finn-Power - Máquina de punzonado CNC

IW 80/150 BTD

Durma - Máquina de punzonado y doblado

C6 + Compact Express

Finn-Power - Máquina de punzonado CNC

X5

Finn-Power - Prensa punzonadora CNC

LPE5 SWUH

Finn-Power - Combinación de punzonado y láser

EM2510NT

AMADA - Máquina de punzonado CNC